Explosion proof receptacle, also called explosion proof receptacles, explosion proof socket, explosion proof plug and socket, flame proof socket, class 1 div 2 receptacle, explosion proof connectors, explosion proof switches and sockets, explosion proof plug, atex sockets, atex plug, flame proof industrial socket, explosion proof industrial sockets, ex sockets, explosion proof 13a switch socket outlet, explosion proof outlet, explosion proof electrical outlets, class 1 division 2 receptacle, power plug explosion proof, flameproof plug socket, explosion proof socket outlet, flameproof plug and socket, dust proof electrical outlets, explosion proof outlet box, explosion proof conduit outlet box, explosion proof receptacle box, class 1 div 1 receptacle.

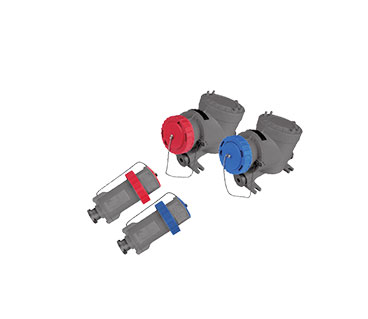

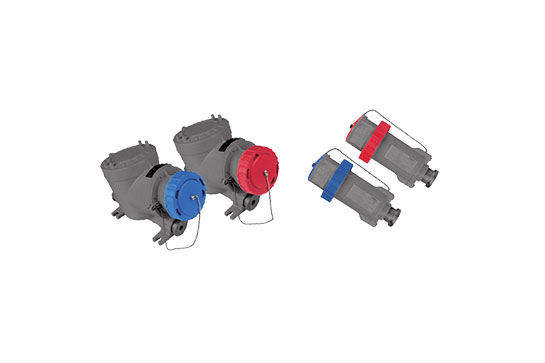

Designed with a confined recessed contacts by flame proof aluminum housing or increased safety plastic housing, explosion proof receptacle are used to contact the electrical power for stationary or portable electrically operated devices such as explosion proof lighting, explosion proof motor, explosion proof air conditioners and other appliances in harsh and hazardous location. No matter connecting single phase loads or three-phase loads, the electrical contact will be deeply hidden and limited without touching directly with explosive gas or dust to avoid any arcing or sparks to stop the explosion happening. For some, you can install those explosion proof receptacle in an enclosed explosion proof enclosure or explosion proof panel for convenient plug-in connection through free-standing or surface mounted bracket.

English

English  Español

Español  português

português  русский

русский  日本語

日本語  العربية

العربية  français

français  Deutsch

Deutsch  한국어

한국어  italiano

italiano  Malay

Malay