-

Product

Lighting By ApplicationLighting By FeaturesExplosion Proof BoxExplosion Proof Fittings

-

Explosion Proof

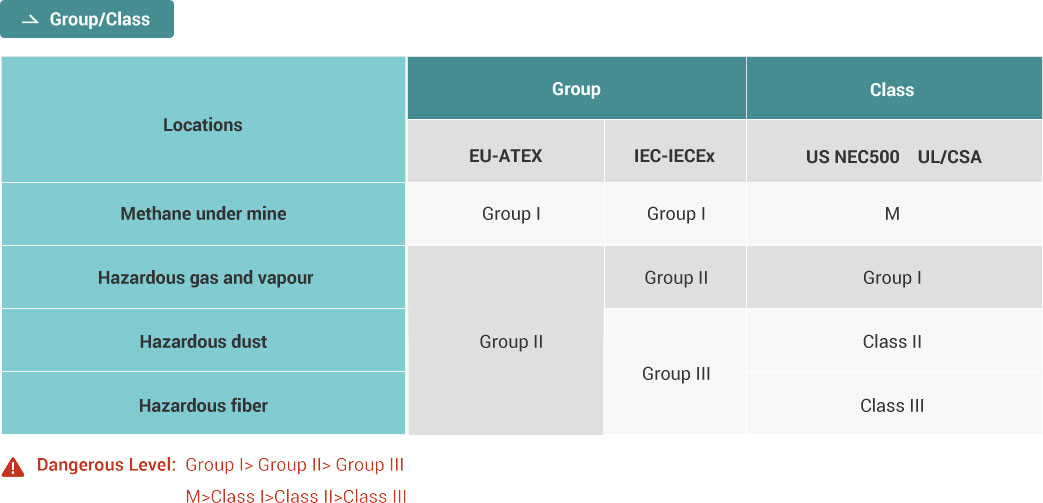

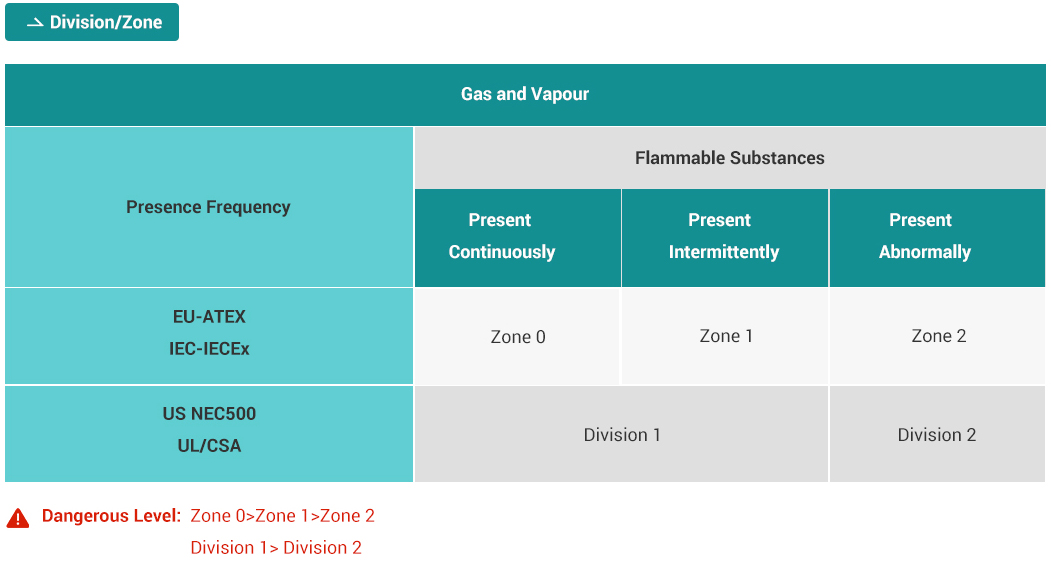

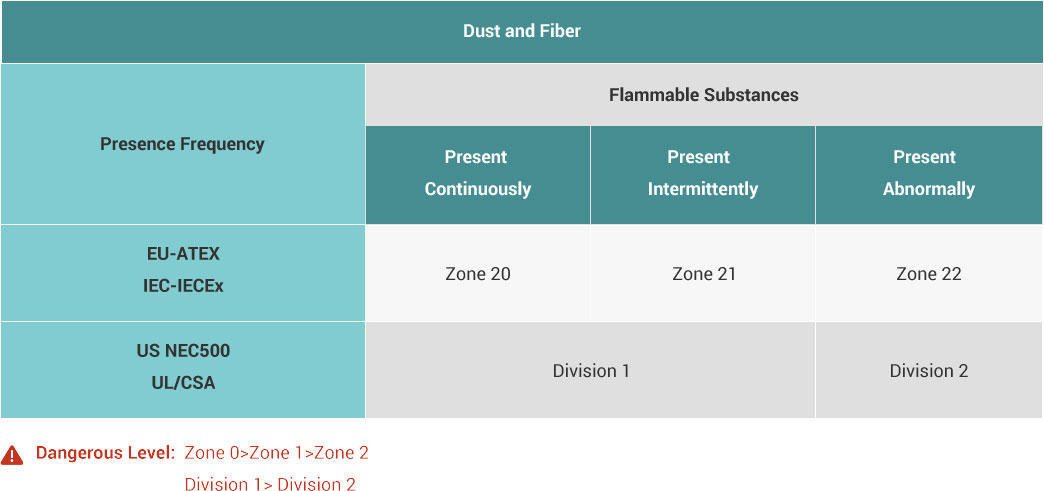

EXPLOSION PROOF NEC Standard

ATEX/IECEx Standard

ATEX/IECEx Standard

-

Markets

ApplicationProjectsOil and Gas Chemical & Pharmaceutical Marine & Ports Mining & Metal Food and Beverage Aviation Industrial & Manufacturing Warehouse Street and Tunnel Others View More +

Each member of the SUREALL team works hard to save energy, reduce budget, maximize durability, bring success to every project for every customer. Here are just a few examples of how we've impacted the markets we're proud to serve.View More +

Each member of the SUREALL team works hard to save energy, reduce budget, maximize durability, bring success to every project for every customer. Here are just a few examples of how we've impacted the markets we're proud to serve.View More +

- Supports

-

Company

About usNewsWelcome to our media center! Here you can find the latest press releases, such as company events, new arrivals of products, whitepaper, industry summit, technical seminars, magazine articles, stories and opinion pieces.View More +

- Contact

×

English

English  Español

Español  português

português  русский

русский  日本語

日本語  العربية

العربية  français

français  Deutsch

Deutsch  한국어

한국어  italiano

italiano  Malay

Malay