Even explosion proof electrical equipment are maintained by many kinds of protection types, responded to the actual market need in gas or dust explosive atmospheres, flameproof "Ex d" protection type play the crucial role, this article may explain to you in easy words for specific requirements for the construction and testing of electrical equipment with flameproof "d" protection, intended for use in explosive atmospheres, indexed by the standard as below:

EN 60079-1, Explosive atmospheres – Part 1: Equipment protection by flameproof "d"

IEC 60079-1, Explosive atmospheres – Part 1: Equipment protection by flameproof "d"

What is Flameproof?

Flameproof means that when an explosion occurs inside the enclosure of the electrical equipment, the flame is ejected through each joint surface without causing the explosive mixture outside the enclosure to explode. Electrical equipment with a flameproof enclosure is called flameproof electrical equipment that can withstand the explosion pressure of the internal explosive gas mixture and prevent the internal explosion from spreading to the explosive mixture around the enclosure.

Why the flameproof enclosure can be used as flameproof?

Flameproof joint/path make flameproof enclosure to be used as flameproof. The joint can act as a flame quencher with the cooling function, so that the flame passing through the joint is sufficiently cooled so that its final temperature is reduced to avoid the ignition of the explosive mixture outside the housing, and the final temperature is below the required minimum temperature to be ignited, so there will be no explosion, and it can play the role of explosion proof and flameproof.

Why can the flameproof joint act as flame quencher?

Figuratively speaking, the flameproof joint provide a specific escaping gap and path and exit to cool the flame.

Strictly speaking, the flameproof joint destroys the flame reaction zone where the combustible mixture burns and explodes, and the flame loses heat during the propagation of the gap. Therefore, after the flame propagates through the gap of the flameproof joint, it becomes greatly smaller and weaker. The temperature is lowered, and it cannot ignite the explosive mixture outside the flameproof enclosure.

Scientifically Speaking, the flameproof joint meet the specific standard and requirements of flameproof protection "d" in EN60069-1 and IEC60079-1 standard currently in force.

Basic Requirements of Flameproof Joint

Now, we analyze the various types of flame joint, you should firstly know some typical types of flameproof joints:

Flanged joint

Spigot joint

Cylindrical threaded joints

Taper threaded joints

1. Non-threaded joint:

There are three critical elements to form non-threaded flameproof joint: valid width of joint, gap of joint, roughness of joint, we will explain two typical joints, flanged joint and spigot joint, for your better understandings.

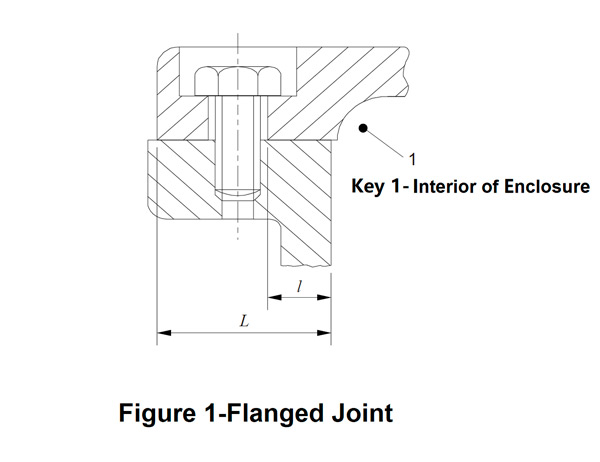

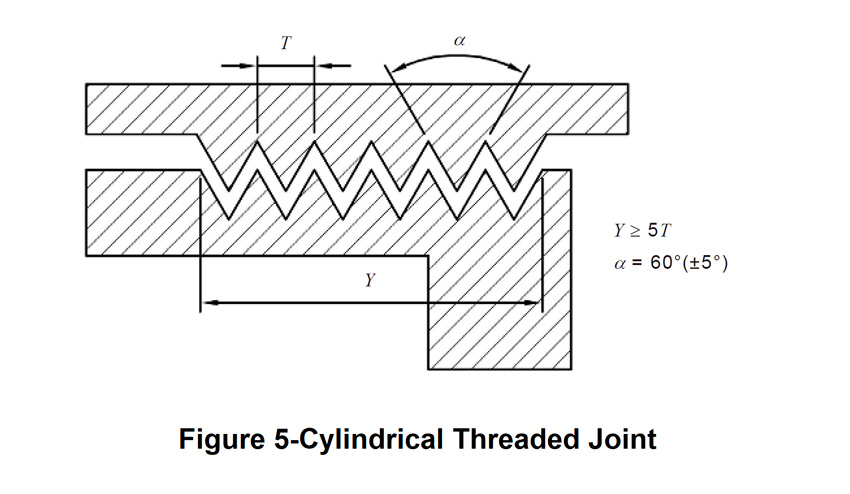

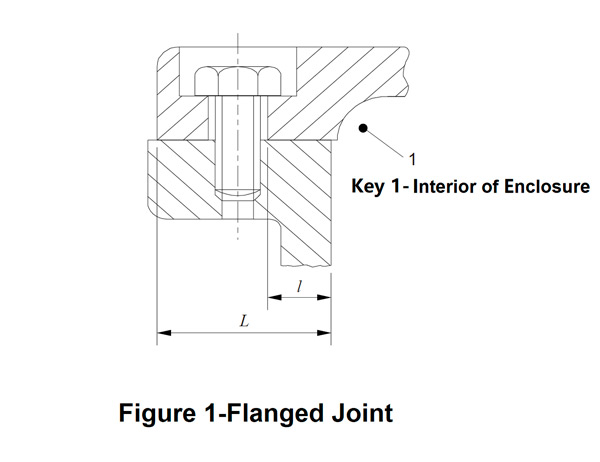

1.1 Flanged joint, see Figure 1

Flanged joint only consist of a plated joint, typical usage in IIB gas group flameproof enclosure.

1.1.1 Width of Joint L

Full width of joint L is shortest path through a flameproof joint from the inside to the outside of an enclosure.

When the width of the flameproof joint L is interrupted by holes intended for the passage of fasteners for assembling the parts of the flameproof enclosure. The valid width of joint l to the edge of the hole shall be equal to or greater than.

a) 6 mm when the full width of joint L is less than 12,5 mm,

b) 8 mm when the full width of joint L is equal to or greater than 12,5 mm but less than 25 mm,

c) 9 mm when the full width of joint L is equal to or greater than 25 mm.

1.1.2 Maximum Gap of Joint

Gap of joint is between the corresponding surfaces of a flameproof joint when the electrical apparatus enclosure has been assembled. It shall be equal to or less than.

a) When the width of joint L is less than 12,5 mm.

0.20mm when internal enclosure volume is equal to or less than 500 m3.

0.08mm when internal enclosure volume is greater than 500 m3 but less than 5,750 m3.

b) When the width of joint L is equal to or greater than 12,5 mm but less than 25 mm.

0.20mm when internal enclosure volume is equal to or less than 2,000 m3.

0.15mm when internal enclosure volume is greater than 2,000 m3.

c) 0.20 mm when the width of joint L is equal to or greater than 25 mm.

1.1.3 Roughness of Joint

The surfaces of joints shall be such that their average roughness Ra does not exceed 6.3 μm.

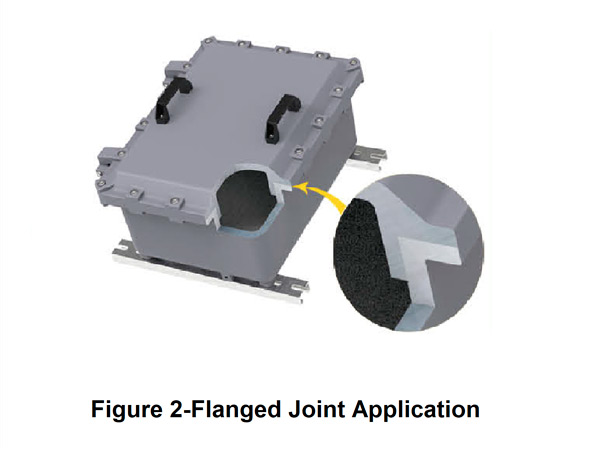

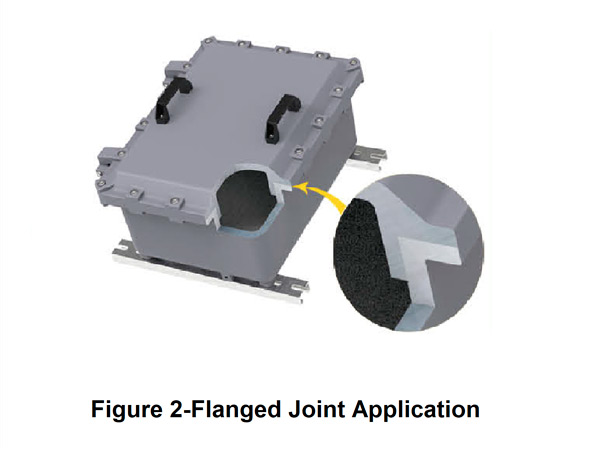

1.2 Spigot joint, see Figure 2

Spigot joint consist of two types, one for cylindrical and plane part spigot joint, the other for cylindrical part spigot joint, typical usage in IIC gas group flameproof lighting and IIC gas group flameproof panel.

1.2.1 Width of Joint L

Full width of joint L is shortest path through a flameproof joint from the inside to the outside of an enclosure.

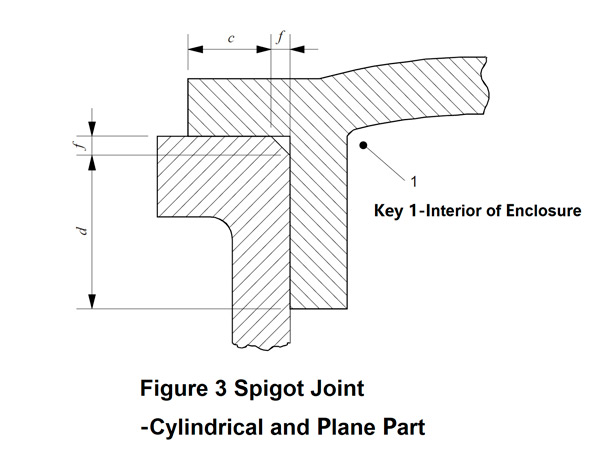

A. Spigot Joint- Cylindrical and plane part, see Figure-3

The width of joint L is defined as the sum of the width d of the cylindrical part and the width c of the plane part, if f is less than or equal to 1 mm. Meanwhile, essential requirements should meet at the same time as below:

L = c + d

c ≥ 6,0 mm

d ≥ 0,50 L

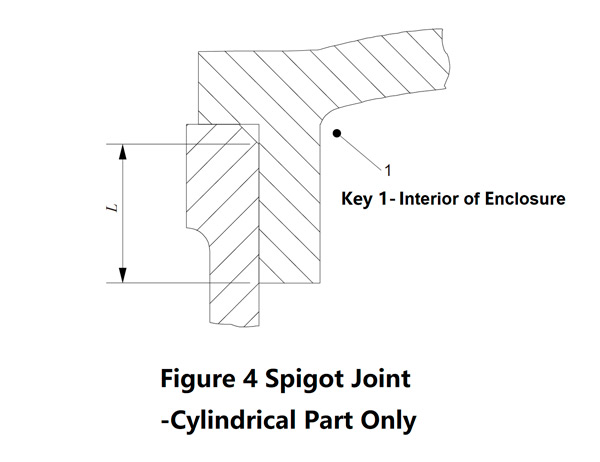

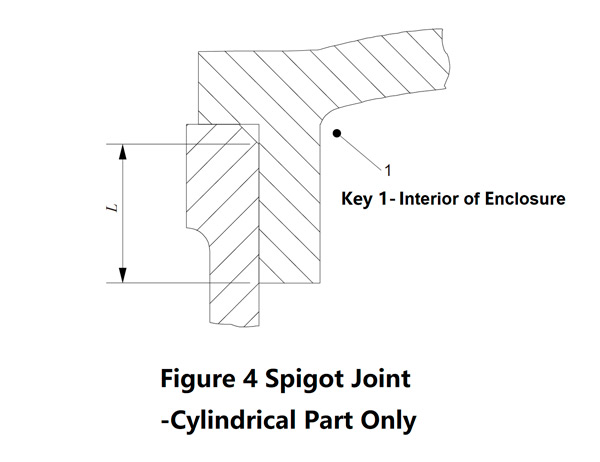

B. Spigot Joint- Cylindrical part, see Figure-4

The width of joint L is defined as the width of the cylindrical part.

1.2.2 Maximum Gap of Joint

Gap of joint is between the corresponding surfaces of a flameproof joint when the electrical apparatus enclosure has been assembled.

A. Spigot Joint- Cylindrical and plane part, see Figure-3

Gap of joint shall be equal to or less than

a) 0.15mm when the full width of joint L is equal to or greater than 12,5 mm but less than 25 mm.

b) 0.18 mm when the full width of joint L is equal to or greater than 25 mm but less than 40 mm, maximum gap of cylindrical part d increased to 0,20 mm if f < 0,5 mm.

c) 0.20 mm when the full width of joint L is equal to or greater than 40 mm, maximum gap of cylindrical part d increased to 0,25 mm if f < 0,5 mm.

B. Spigot Joint- Cylindrical part, see Figure-4

Gap of joint shall be equal to or less than

a) 0.15mm when the full width of joint L is equal to or greater than 12,5 mm but less than 40 mm.

b) 0.20 mm when the full width of joint L is equal to or greater than 40 mm.

1.1.3 Roughness of Joint

The surfaces of joints shall be such that their average roughness Ra does not exceed 6.3 μm.

2. Threaded joint:

Different thread joints will have varied requirements, we will explain two typical thread joints, cylindrical threaded joint and taper threaded joint, for you.

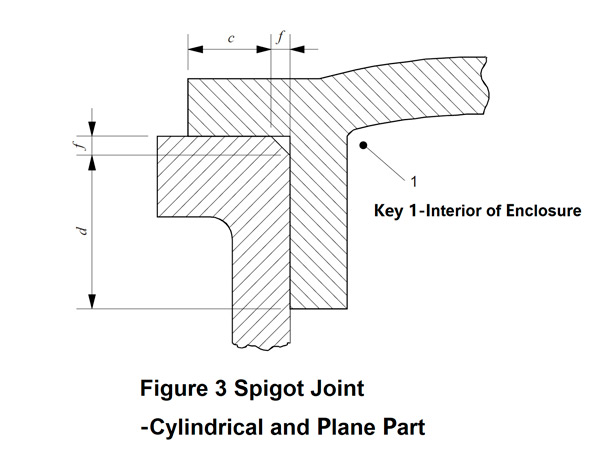

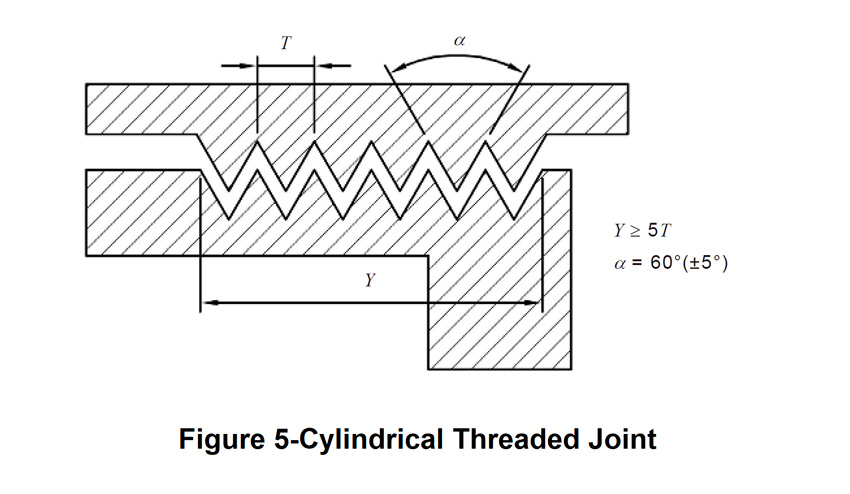

2.1 Cylindrical threaded joint, see Figure 5

Cylindrical threaded joint are engaged under metric thread, such as M25x1.5 thread, main application in IIC gas group explosion proof light fittings or IIC gas group explosion proof cable glands or IIC gas group explosion proof conduit fittings.

2.1.1 The number of engaged threads shall be equal to or more than 5;

2.1.2 Every pitch of engaged thread shall be equal to or more than 0.7mm, Where the pitch exceeds 2 mm, special manufacturing precautions may be necessary (for example, more threads engaged) to ensure that the electrical equipment can pass the test for non-transmission of an internal

ignition.

2.1.3 Thread form and quality of fit shall be medium or fine tolerance quality according to ISO 965-1 and ISO 965-3.

2.1.4 Depth of engagement shall be equal to or more than:

A. 5mm, when the internal enclosure volume is equal to or less than 100cm3

B. 8mm, when the internal enclosure volume is more than 100cm3

2.2 Tap threaded joint

Tap threaded joint are engaged under tap thread, such as NPT 1/2" thread, main application in gas group IIC for explosion proof light fittings, explosion proof panel, explosion proof cable glands, explosion proof conduit fittings.

2.2.1 The number of engaged threads shall be equal to or more than 5;

2.2.2 Internal and external thread shall have the same nominal size. Threads shall conform to the NPT requirements of ANSI/ASME B1.20.1.

Corrosion Protection Requirements for Flameproof Joint

The surface of joints may be protected against corrosion. Coating with paint or powder-coat finish is not permitted. Corrosion inhibiting grease, such as petrolatum or soap-thickened mineral oils, may be applied to joint surfaces before assembly. The grease, if applied, shall be of a type that does not harden because of ageing, does not contain an evaporating solvent, and does not cause corrosion of the joint surfaces.

Joint surfaces may be electroplated. The metal plating, if applied, shall be in accordance with the following:

if not more than 0,008 mm thick, no additional consideration is necessary;

if more than 0,008 mm thick, then the maximum gap without the plating shall still be in accordance with the applicable joint requirements and shall be tested for flame transmission based on the gap dimension that would exist without the plating.

ATEX/IECEx Standard

ATEX/IECEx Standard

Each member of the SUREALL team works hard to save energy, reduce budget, maximize durability, bring success to every project for every customer. Here are just a few examples of how we've impacted the markets we're proud to serve.View More +

Each member of the SUREALL team works hard to save energy, reduce budget, maximize durability, bring success to every project for every customer. Here are just a few examples of how we've impacted the markets we're proud to serve.View More +

English

English  Español

Español  português

português  русский

русский  日本語

日本語  العربية

العربية  français

français  Deutsch

Deutsch  한국어

한국어  italiano

italiano  Malay

Malay