Ⅰ. How to choose LED high bay lamps?

In the selection of high bay lamps, we can choose the light source of high bay lamps, which have the characteristics of high thermal conductivity, low light decay, pure light color, and no ghosting; however, through the integrated design of superconducting heat transfer and lamp heat dissipation, the heat is quickly conducted and diffused, so that the product is smaller in size, lighter in weight and better in heat dissipation.

Of course, high bay lamps with good heat dissipation are more popular with customers. High bay lights are constantly changing to design a reasonable but practical one. In the designer's constant pursuit of quality improvement, we can find suitable high bay lights from different jobs.

Energy-saving high bay lamps use energy-saving technology on the basis of traditional high bay lamps to make high bay lamps save power consumption and improve illuminance, thereby saving investment funds.

It can save energy from three aspects: light source + electrical appliances + lamps. To provide the reflection efficiency of explosion proof high bay led lamps, electrical appliances can use BERSN electronic ballasts with high power factor and low power consumption. Electronic ballasts are small in size and light in weight, much lighter than magnetic ballasts, which can reduce the force on the ceiling, and the light source can use high-efficiency energy-saving industrial and mining lamps.

Ⅱ. Requirements for the use of LED high bay lamps

1. In order to meet the visual needs of different production and the needs of installation conditions of lamps, the reflector of high bay lamps, like 500w led high bay, should be able to produce light distributions of various widths. The surface is painted and glazed to make it appear white, and the reflector made of aluminum, glass mirror, prism glass and other materials can get a wide light distribution, suitable for large-area, vertical or near-vertical workplaces.

For tall factory buildings and places with tall machine tools that require separate lighting, reflectors made of materials with strong light control properties such as prism glass, mirror glass, and polished aluminum can be used.

2. In a dusty environment, closed lamps or convective lamps with upward light flux should be used.

3. Attention should be paid to the airtightness of the shell and the surface treatment of the reflector in a humid environment; generally, open-type lamps are commonly used indoors, and enamel surface reflectors, aluminum reflectors with thick aluminum oxide film on the surface or aluminum reflectors coated with silicon dioxide protective film are used;

4. Considering the inevitable vibration in the production site, the fixed light source should adopt the anti-loosening lamp holder, etc.

There are many ways to fix LED high bay lights. General lighting has the form of ceiling, embedded, hoisting (straight tube or chain). The movable local lighting is equipped with corresponding hooks, handles, clamp feet, etc.;

5. Fixed local lights are generally firmly locked on the working machine with screws or fixing mechanisms.

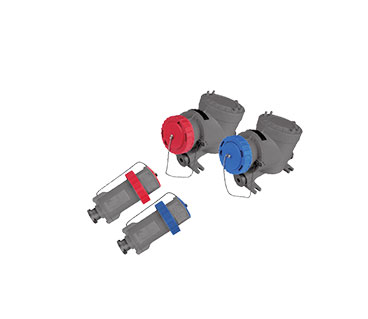

ATEX/IECEx Standard

ATEX/IECEx Standard

Each member of the SUREALL team works hard to save energy, reduce budget, maximize durability, bring success to every project for every customer. Here are just a few examples of how we've impacted the markets we're proud to serve.View More +

Each member of the SUREALL team works hard to save energy, reduce budget, maximize durability, bring success to every project for every customer. Here are just a few examples of how we've impacted the markets we're proud to serve.View More +

English

English  Español

Español  português

português  русский

русский  日本語

日本語  العربية

العربية  français

français  Deutsch

Deutsch  한국어

한국어  italiano

italiano  Malay

Malay